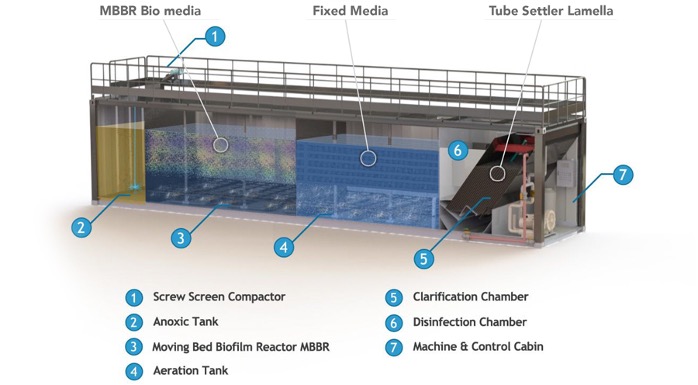

Ecocycle MBBR mobile wwtp system is a highly effective biological treatment process based on a combination of conventional activated sludge process and biofilmmedia.

Ecocycle MBBR compact systems contains all necessary stages, such as physical treatment ( primary treatment), anoxic chamber, aeration, clarification, disinfection, sludge storage section and all the mechanical - electrical equipment’s, piping, and instrumentation inside its compact structure as a mobile system.

Ecocycle MBBR provides easy installation and operation. Biofilm media provides increased surface area for the biological micro- organisms to attach and grow. The increased surface area reduces the footprint of the tanks required to treat the wastewater.

Ecocycle MBBR is a highly effective activated sludge process and bio-filter process that uses small Biofilm carrier elements Biochip or “media” (polyethylene) to aid in biofilm growth. These medias have density lighter than water so they dont sink and tend to float . The media is continuously agitated by bubbles from the aeration system that adds oxygen at the bottom of the first compartment of the aeration tank.

- The media provides increased surface area for the biological microorganisms to attach to and grow in the aeration tanks.

- The increased surface area reduces the footprint of the tanks required to treat the wastewater.

- Ecocycle MBBR saves process times and tank space.

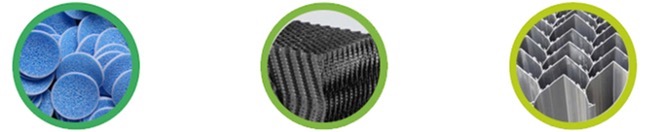

MBBR Bio media

Bio media provides increased surface area for the biological microorganisms to attach and grow.

Fixed Media

This media includes high surface area, provide a large internal surface area for the growth of microorganisms.

Tube Settler Lamella

High-Rate Inclined Plate Lamella Clarifier for Wastewater Sedimentation.

Basic process steps

- Screening

- Denitrification

- Nitrification

- Aeration

- Clarification

- Sludge Stabilization

- Disinfection

Wastewater fed by gravity or pumping is treated in aeration chamber so that bacteria inside converts the organic matter of wastewater into CO2 and water.

Compact treatment units - plants are covered under service and maintenance warranty. Our company provides replacement parts and technical service for the subsequent years.

AREAS OF USING PACKAGE TREATMENT PLANTS

- Summer housing developments

- Holiday villages

- Housings and mass housings

- Factories and Industrial Facilities

- Villages, towns and Municipalities

- Schools, Hospitals and Military Facilities

- Accommodation Facilities and Restaurants

- Temporary locations such as construction sites

- Recreational facilities Camps

Advantages of Ecocycle® MBBR Compact Package WWTP Units

- Less Space Requirement

- Recycling for irrigation

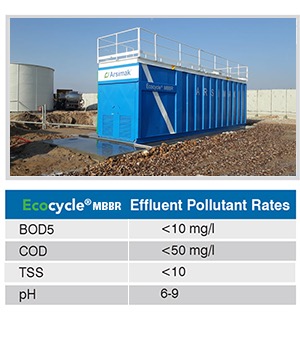

- Higher Outlet Water Quality

- Silence and Odorless

- Advanced Processing Technology

- High Efficiency in Different Flow Rates

- Low Initial Investment and Operating Cost

- Resistant to Different Temperature

- Easy Installation & Commissioning

The technology used is ideal for applications where trained operators are not in place or where minimal operator entry is required. Modular design makes it easy to increase the number of units according to capacity.

That's why Ecocycle® MBBR WWTP solutions are the best choice for a low-cost, automated and reliable wastewater treatment plant.

- Ease of operation

- Modular design allows expansion

- Quick installation and start up

- Low operating expenditure

- Small footprint

- Low energy consumption

- Discharge quality to environmental standards

- Fully automated

Arsimak designs and manufactures the Ecocycle® units in suitable sizes when it will reach by ship transportation. Ecocycle® can be transported 20ft./40ft./40ft.HC Open Top containers.

Products and components are sourced from reputable suppliers and OEMs locally and internationally, providing you with the best quality possible.

Arsimak provides a wide range of after-sale support and services to help our customers make the most of their assets.